Smart lockers for distribution centers have revolutionized equipment management for warehouse operations worldwide. This case study reveals how one Midwest distributor with 10 facilities eliminated device losses completely using HonestWaves custom smart lockers with RFID tracking and real-time monitoring. Within 60 days, they achieved 100% reduction in unreported device losses, saved 5+ hours per week per location on management oversight, and realized ROI in under 3 months. The key benefits included improved productivity, greater accountability, and enhanced workflow efficiency across all locations. The system helped staff and managers save time by streamlining asset management and reducing manual tracking efforts. Users also enjoyed the convenience of seamless device pick-up and return, making daily operations easier and more accessible.

The Problem – $2,000 Devices Disappearing from Distribution Centers

A leading Midwest distributor with 10 facilities had a recurring and expensive issue: Zebra and Honeywell scanners kept disappearing from the floor. Drivers were losing iPads and printers. Devices were returned damaged, often without anyone noticing until days – or weeks – later. The cost? Tens of thousands of dollars per year. A lack of systematic inventory and asset management meant there was no centralized way to track or monitor devices, contributing to recurring losses and inefficiencies.

On top of that, the checkout process was chaotic. Managers had to manually unlock storage rooms, and shifts would bottleneck while waiting for access to devices.

The distributor needed smart lockers for distribution centers that could handle industrial-grade equipment tracking, not just simple phone charging—they needed enterprise-level device management.

The Discovery – HonestWaves’ Embedded Research Revealed Critical Workflows

Our team at HonestWaves didn’t just ship lockers – we embedded ourselves. We flew out to observe shift arrivals, clock-out routines, and equipment handoffs at several locations. We interviewed pickers, drivers, shift managers, and IT staff to understand the pain on the ground. To ensure a comprehensive view, we engaged with multiple departments, such as operations, IT, and logistics, to understand the full scope of equipment management challenges.

This hands-on approach is core to HonestWaves’ methodology: understanding real workflows before designing custom solutions.

Key Findings from On-Site Research

What we discovered was clear:

- Two distinct workflows: fulfillment teams using Honeywell scanners + RelayX radios and drivers using iPads + portable printers

- Manual tracking chaos with no systematic approach to device accountability

- No damage reporting process leading to undetected equipment deterioration

- Zero accountability for time-out, late returns, or damaged gear

The HonestWaves Smart Locker Solution: Custom-Built for Real Operations

We deployed HonestWaves’ 20-Bay Smart Charging Locker units across all 10 distribution center locations. This industrial-grade model was specifically chosen for its capacity to handle multiple device types simultaneously while providing the robust security and tracking features required for expensive scanning equipment. These advanced electronic locker systems are designed for secure, customizable storage and device management.

The 20-Bay Smart Charging Locker proved ideal for distribution center operations with its ability to charge up to 20 devices simultaneously, keyless access options, and cloud-based management system that enabled real-time monitoring across all locations. Administrators can remotely monitor and manage the lockers using specialized software. The lockers are designed for indoor environments, with durable finishes suitable for warehouse interiors.

We custom-built a dual-role smart locker system with embedded intelligence that matched the reality of their operations.

Key features include:

Configurable compartments to store personal items securely for employees during their shifts

Simultaneous charging for up to 20 devices

Secure, keyless access via PIN, RFID, or QR code for contactless device retrieval

Cloud-based management and usage analytics

Core HonestWaves Smart Locker Features Deployed

Here’s what we delivered using HonestWaves’ customizable smart lockers for distribution centers:

- RFID Access Control: Leveraging HonestWaves’ multiple access options, each device received unique RFID tagging while staff used RFID badges for seamless equipment checkout

- RFID Tagging: Each device received a unique RFID sticker

- Role-Based Dispensing: When staff scanned their HID badge, the locker recognized their role and dispensed the most charged device of the correct type

- Timed Checkouts: Locker tracked how long each device was out, with max time thresholds and alerts for overdue returns

- Return Verification: Staff had to badge in personally to verify their identity (no “buddy returns”)

- Damage Flagging: Upon return, staff were prompted to indicate if the device was damaged

- Visual Logging: A top-mounted camera snapped a 5-second image or video of the returned device to document condition

- Locked Bays for Flagged Devices: If a device was marked damaged, that bay locked until a manager could investigate

- Backend Dashboard: Provided managers with real-time visibility, alerts, and analytics-cutting down administrative overhead

Types of Lockers for Distribution Centers

Distribution centers operate in fast-paced environments where secure storage and efficient asset management are critical. Smart lockers offer a versatile solution, providing controlled access and reliable storage for a wide range of needs. Here are the main types of lockers commonly used in distribution centers, each designed to support specific operational requirements:

1. Asset Management LockersThese smart lockers are purpose-built for managing valuable equipment such as barcode scanners, tablets, laptops, and handheld devices. With secure storage and real-time tracking, asset management lockers ensure that only authorized employees can access essential assets, reducing the risk of loss or theft. Controlled access features, such as RFID or PIN entry, help maintain accountability and streamline device retrieval during shift changes.

2. Parcel Delivery LockersDesigned to handle the constant flow of packages, parcel delivery lockers provide a secure and organized way to store incoming and outgoing shipments. These lockers offer convenient access for both employees and delivery personnel, reducing bottlenecks and supporting efficient package handling. Automated notifications and tracking features help streamline operations and ensure packages are retrieved promptly.

3. Employee LockersEmployee lockers are essential for storing personal items, uniforms, and shift-specific equipment. Smart locker systems offer enhanced security and controlled access, allowing staff to safely store their belongings while on the job. These lockers can be configured to support individual or shared use, adapting to the exact needs of the workforce and maximizing available storage space.

4. Custom Smart Locker SolutionsEvery distribution center has unique operational challenges. Custom smart locker solutions can be tailored to fit specific workflows, device types, and security requirements. Whether you need lockers with variable bay sizes, integrated charging capabilities, or advanced software for asset control, a custom solution ensures your storage system aligns perfectly with your business processes.

By selecting the right combination of smart lockers, distribution centers can optimize storage, protect valuable assets, and enhance operational efficiency. The flexibility and security offered by modern locker systems make them an essential component of any high-performing warehouse environment.

Advanced Integration: HonestWaves API Capabilities

To further streamline access management, HonestWaves built a custom API integration with the customer’s ADP payroll system. This showcased the flexibility of HonestWaves’ platform beyond standard charging locker applications.

The integration allowed smart locker access to be automatically provisioned for new hires based on their role—and just as importantly, deactivated for employees removed from the payroll system. This level of automation, available through HonestWaves’ customizable software platform, eliminated manual updates and access risks tied to outdated employee records.

HonestWaves Technology Specifications for Distribution Centers

The 20-Bay Smart Charging Locker Deployment

For this distribution center implementation, HonestWaves deployed our 20-Bay Smart Charging Locker units specifically designed for warehouse and distribution center environments. This model provided the perfect balance of capacity, security, and advanced features needed for managing expensive scanning equipment.

Hardware Configuration

- Model Deployed: HonestWaves 20-Bay Smart Charging Locker with industrial-grade construction

- Capacity: 20 simultaneous device charging and storage positions per unit

- Mounting: Floor-standing units optimized for high-traffic distribution areas

- Bay Customization: Variable compartment sizes to accommodate different device types (Zebra scanners, iPads, Honeywell devices, portable printers)

- Access Technology: Keyless entry with combined RFID, PIN code, and biometric systems for maximum security

- Charging Features: High-speed charging with overcharge protection, short-circuit prevention, and temperature control

- Safety Standards: Advanced safety features essential for protecting valuable electronics in industrial environments

Software Intelligence

- Private Mode Configuration: HonestWaves’ Private Mode software allowed assignment of specific bays to specific roles (fulfillment vs. drivers)

- Real-Time Monitoring: Live dashboard showing device location, battery status, and checkout duration

- Automated Alerts: Configurable notifications for overdue returns, damage reports, and system maintenance

- Analytics Reporting: Comprehensive usage data for optimizing equipment allocation and identifying patterns

The Impact: 100% Reduction in Device Losses Within 60 Days

Within 60 days of implementing the HonestWaves smart lockers for distribution centers, the distributor saw a 100% reduction in unreported device losses—a dramatic transformation that exceeded expectations.

The HonestWaves system eliminated:

- Device disappearance through automated RFID checkout accountability

- Delayed returns with real-time tracking and automated alerts

- Disputes over who damaged what via integrated visual logging and biometric verification

- Shift delays from manual access through HonestWaves’ role-based automated dispensing

Meanwhile, managers gained access to HonestWaves’ powerful analytics dashboard and got hours of their time back each week.

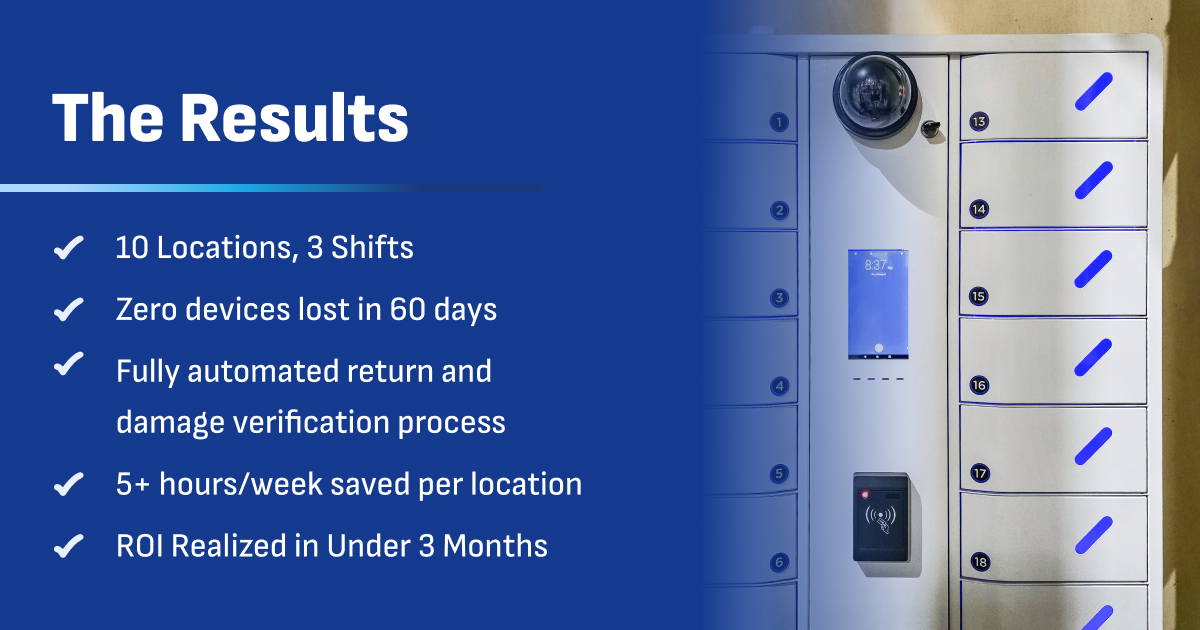

Quantified Results with HonestWaves 20-Bay Smart Locker Implementation

- 10 Locations across the Midwest with 3 shifts each

- 10 HonestWaves 20-Bay Smart Charging Locker units deployed (view product details)

- 200 total charging bays providing comprehensive device coverage across all facilities

- Zero devices lost in 60 days post-implementation

- Fully automated return and damage verification through HonestWaves platform

- 5+ hours per week saved per location on manager oversight

- ROI realized in under 3 months from reduced losses and time savings

- 99.9% system uptime with HonestWaves’ reliable hardware and software

Direct Feedback from Staff

“The best part is we’re not chasing down missing devices anymore,” said one shift supervisor. “The system tracks everything automatically, so we’re not wasting time playing detective.”

★★★★★

“Each week, one of us is on-call after hours across all locations. Before the lockers, we’d regularly get pinged by drivers or pickers asking where their device was or if someone else had checked it out,” said the IT manager of one facility. “Now, those calls are practically gone.”

★★★★★

Why HonestWaves Smart Lockers Outperformed Traditional Solutions

Beyond Basic Charging Lockers

While many companies offer basic phone charging lockers, HonestWaves’ platform proved uniquely suited for industrial device management in distribution centers:

Customization Capabilities:

- Variable bay sizes for different equipment types

- Industrial-grade construction for 24/7 operations

- Role-based access control impossible with standard charging stations

Enterprise Integration:

- API connectivity with existing business systems

- Real-time data analytics for operational optimization

- Scalable software platform supporting multiple locations

Advanced Security Features:

- Data-blocking technology protecting against cyber threats

- Multi-factor authentication (RFID + biometric)

- Comprehensive audit trails for compliance requirements

Smart Lockers for Distribution Centers vs. Standard Equipment Storage

| Feature | Traditional Storage | HonestWaves Smart Lockers |

|---|---|---|

| Access Control | Manual keys/codes | RFID + Biometric + PIN |

| Device Tracking | Paper logs | Real-time RFID tracking |

| Damage Documentation | None | Automated visual logging |

| Usage Analytics | None | Comprehensive dashboard |

| Integration | None | Custom API development |

| Accountability | Honor system | Multi-layer verification |

Industry Applications Beyond Distribution Centers

While this case study focuses on smart lockers for distribution centers, HonestWaves’ customizable platform applies to various industries facing similar device tracking challenges:

Events and venues: Temporary or permanent solutions for attendee device security and charging needs.

Corporate offices: Smart lockers provide secure storage, package handling, and access management for employees and visitors, streamlining internal logistics and improving workplace efficiency.

Public safety organizations: Law enforcement, emergency services, and other community safety departments use smart lockers to ensure secure access to critical equipment and maintain chain-of-custody protocols.

Retailers: Smart lockers facilitate contactless order pick-up, supporting BOPIS (Buy Online, Pick Up In Store) solutions. Customers can conveniently buy online and retrieve their orders from smart lockers, enhancing retail fulfillment and customer satisfaction.

Hospitals and healthcare: Secure device storage and management for staff and visitors.

Universities and schools: Device charging and secure storage for students and faculty.

Manufacturing Facilities

- Test equipment management using HonestWaves’ Private Mode for calibrated instruments

- Tool tracking with customizable bay configurations for different equipment sizes

- Safety device accountability leveraging biometric access for critical protective equipment

Healthcare Organizations

- Mobile device management with data-blocking technology for HIPAA compliance

- Medical equipment tracking using real-time monitoring for expensive diagnostic tools

- Medication security through HonestWaves’ multi-access authentication options

Retail Operations

- POS device management with role-based dispensing for different staff levels

- Communication equipment tracking across multiple store locations

- Asset protection using integrated visual documentation for high-value items

Field Service Companies

- Diagnostic equipment control with automated checkout/return processes

- Tool accountability across multiple technician teams

- Equipment maintenance tracking through HonestWaves’ analytics platform

Getting Started with Smart Lockers for Distribution Centers Implementation

Phase 1: Assessment and Design

HonestWaves begins every smart lockers for distribution centers implementation with embedded operational research:

- Workflow Analysis: Understanding current equipment management processes

- Stakeholder Interviews: Gathering requirements from end users and managers

- Custom Configuration: Designing bay layouts, access controls, and integration needs

- ROI Projections: Calculating expected savings and payback timeline

Phase 2: Custom Development

Leveraging HonestWaves’ flexible platform:

- Hardware Customization: Configuring locker specifications for your equipment

- Software Configuration: Setting up role-based access, alert thresholds, and reporting

- Integration Development: Connecting with existing business systems via API

- Security Setup: Implementing appropriate access controls and data protection

Phase 3: Pilot and Rollout

- Single Location Testing: Proving concept and refining configuration

- Staff Training: Ensuring smooth adoption of HonestWaves system

- Performance Monitoring: Tracking results and optimizing operations

- Multi-Location Deployment: Scaling successful pilot to additional facilities

Phase 4: Ongoing Optimization

- Analytics Review: Regular analysis of usage patterns and optimization opportunities

- Feature Updates: Accessing new capabilities as HonestWaves enhances the platform

- Expansion Planning: Adding locations, bays, or equipment types as needs grow

- Continuous Support: Ongoing technical support and system maintenance

Why Choose HonestWaves Smart Lockers for Distribution Centers

Proven Track Record

With over 100,000 charging stations worldwide, HonestWaves brings enterprise-scale experience to custom device management solutions. Our success in transforming this distribution center’s operations demonstrates our ability to adapt phone charging locker technology for complex industrial applications.

Customization Expertise

Unlike one-size-fits-all solutions, HonestWaves specializes in understanding your unique operational requirements and building smart lockers for distribution centers that match your workflows, not the other way around.

Comprehensive Support

From initial assessment through ongoing optimization, HonestWaves provides:

- 24/7 Technical Support: Phone: 562-800-6997, Toll Free: 888-887-0758

- Professional Services: Custom development and integration support

- Training and Change Management: Ensuring successful user adoption

- Continuous Innovation: Regular platform updates and new feature development

Compliance and Security

HonestWaves maintains strict compliance standards and security protocols, essential for enterprise deployments:

- Data-blocking technology preventing cyber threats

- Comprehensive audit trails for regulatory compliance

- Secure API integrations protecting sensitive business data

- Multi-layer access controls preventing unauthorized equipment access

Next Steps: Transform Your Equipment Management with Proven Solutions

This distribution center case study demonstrates how HonestWaves’ 20-Bay Smart Charging Locker can transform equipment management from a costly problem into a competitive advantage. By combining RFID technology, role-based automation, and comprehensive accountability in a single, robust unit, organizations can eliminate device losses while improving operational efficiency.

The 20-Bay model proved perfect for distribution center operations, providing enough capacity for multiple device types while maintaining the industrial-grade durability required for 24/7 warehouse environments.

Ready to Stop Bleeding Devices at Your Facility?

Contact HonestWaves today to explore how our customizable smart lockers for distribution centers can transform your equipment management operations:

- Schedule a Consultation: Discuss your specific device tracking challenges

- Request a Custom Quote: Get pricing for your facility’s requirements

- Arrange a Demo: See HonestWaves technology in action

- Start Your Assessment: Begin with embedded operational research

Contact Information:

- Email: info@honestwaves.com

- Phone: 562-800-6997

- Toll Free: 888-887-0758

- Support Hours: Monday-Saturday, 6:00 AM – 6:00 PM PST

The HonestWaves Difference

The key lesson from this success story: effective equipment tracking requires more than just technology—it demands understanding real workflows, designing for actual user needs, and creating systems that make accountability easier rather than more burdensome.

HonestWaves’ approach of embedded research, custom development, and ongoing optimization ensures your smart lockers for distribution centers solution delivers measurable results from day one.

Don’t let valuable equipment walk away from your facility. HonestWaves smart lockers provide the accountability, automation, and analytics you need to protect your assets and optimize your operations.

Summary

- 10 Locations across the Midwest with 3 shifts

- Zero devices lost in 60 days

- Fully automated return/damage verification

- 5+ hours/week saved per location on manager oversight

- ROI Realized in Under 3 Months

Frequently Asked Questions About Smart Lockers for Distribution Centers

What makes smart lockers suitable for distribution centers?

Smart lockers for distribution centers are specifically designed with industrial-grade construction, role-based access controls, and real-time tracking capabilities that standard storage solutions cannot provide. They handle multiple device types, support 24/7 operations, and integrate with existing business systems.

How quickly can smart lockers be implemented?

Based on our distribution center case study, HonestWaves typically completes implementation within 30-45 days from initial assessment to full deployment. The 60-day results timeline includes this implementation period plus performance measurement.

What devices can smart lockers manage?

HonestWaves smart lockers for distribution centers can accommodate Zebra scanners, Honeywell devices, iPads, tablets, portable printers, radios, and virtually any handheld equipment used in warehouse operations. Bay sizes are customizable for different device types.

How do smart lockers integrate with existing systems?

HonestWaves provides custom API development to connect with payroll systems (like ADP), warehouse management systems, and other business applications. This enables automated user provisioning and seamless workflow integration.

What is the typical ROI timeline for smart lockers?

Based on this case study, the distribution center achieved ROI in under 3 months through eliminated device losses and reduced management overhead. ROI varies by facility size and current loss rates.